We are delighted to announce the 2018 Artist Fellows and Finalists in the Traditional Arts, awarded by Mass Cultural Council. Fellows each receive $12,000 and Finalists each receive $1,000. The next opportunity to apply for these awards will be October of 2019.

ARTIST FELLOWS:

Kieran Jordan, Traditional Irish step dance

At the age of five, Kieran Jordan watched Irish step dancing for the first time in a St. Patrick’s Day parade. Soon after, she was taking lessons in her parish hall on Saturday mornings. Thus began her life-long journey to becoming not only a renowned Irish step dancer, but also a cultural activist and an invaluable resource within the Irish-American community.

Jordan is a gifted dancer, choreographer, and teacher of old style Irish step dances, a tradition that is intricately tied to Irish history, local culture, and traditional music. She displays the aesthetic assurance that naturally evolves from the dedication of a gifted artist who has danced competitively within the Irish traditional step-dancing sphere.

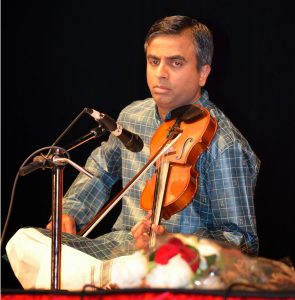

Panayotis League, Greek lauto playing and oral poetry

Panayotis League specializes in traditional Greek music and oral poetry indigenous to the Greek island of Kalymnos, Crete, and their diaspora communities. With family roots in the Greek community of Tarpon Springs, Fla, League pursued his interest in traditional music by journeying to the Greek islands to study laouto and tsabouna, with older master musicians on Kalymnos in 2001 and violin on Crete in 2003.

Today League is one of the few in the US who specializes in the laouto music of Kalymnos. In addition to concerts and festivals, he is a frequent performer at local marriage celebrations, baptisms, and feast days in the Greek diaspora community. He is also a scholar of Greek music. His dissertation focused on the music of Boston’s Anatolian Greek diaspora. League is currently a postdoctoral fellow at Harvard’s Milman Parry Collection of Oral Literature, where he is managing the digitization and cataloguing of James Notopoulos’ field recordings from his 1952-53 trip to Greece and Cyprus.

Sidi Joh Camara, Malian dance and drumming

Sidi Mohamed “Joh” Camara grew up in Bamako, Mali surrounded by musicians, praise singers, and story-tellers. He began his formal training with Mouvement Pionnier, and then went on to work with Troupe Sewa and Troupe Districte de Bamako before relocating to the United States in 1996. He has experienced West African dances in their purest traditional form, where a particular dance is unique to that village and the movements have remained unchanged for centuries. Though West African dance companies in urban centers keep the traditions alive, often the context and meaning in which these village dances originated gets lost. “Once they are performed by dance companies in the cities, they are taken out of context. . . As a ballet, it is no longer a part of the ceremony it accompanies.”

Joh’s research has taken him all over Mali to see the dances in the ceremonies of which they are a part. He and his young son Tiemoko were awarded a 2017 MCC Traditional Arts Apprenticeship They focused on the learning of four dances (Didadi, Korodjuga, Mandiani, and Madan), the songs that accompany these dances, as well as why and in what context they are danced. Father and son will also take part in ceremonies within the Malian and Guinean diaspora community both here and in New York.

FINALISTS:

Geoffrey Kostecki, liturgical painting

Geoffrey Kostecki excels at the sacred art known as liturgical painting. As a young man, he was inspired by the powerful imagery of Catholicism, first created for the Church during the Renaissance. Kostecki moved to Italy to study at University Lorenzo Di Medici in Florence. There he gained advanced painting techniques required for liturgical painting which include site-specific design, fresco painting, figurative sculpting, stencil design, gilding, and marbleizing.

After returning home and earning an MFA, Kostecki apprenticed under figurative painter Graydon Parrish, who himslef had trained through the Atelier method, and with trumpe-l’oeil painter Robert Bock.

Kostecki’s original work and restorations can be seen in churches throughout Central Massachusetts and upstate New York, including St. Paul’s Church in West Warren, St. John’s in Worcester, and the 30 x 40 feet nave mural depicted here, commissioned by St. Agnes Church in Lake Placid, NY.

Fabian Gallon, Colombian tiple player

Fabian Gallon grew up in Pereira, the mountainous coffee region of Colombia, where he learned to play the tiple from his father and brothers. He went on to study with Maestro Benjamin Cardona before entering the conservatory of Universidad Technologica of Pereira.

Similar in shape but distinct from the guitar, the 12-stringed tiple is considered the national instrument of Colombia. It recently gained a renaissance when it began to be played more as a solo instrument. The style Gallon developed went from simple strumming to a complex blend of sophisticated picking and rich variations of strumming figures.

Before moving to Boston, Gallon was very active in Bogata’s musical scene, performing and recording with Trio Ancestro, as well as dedicating himself to bringing up the next generation of leading Colombian tiple players. He recently recorded with several Latin American musicians in Boston. He continues a tradition of well-known tiple players like Gonzalo Hernandez, Pacho Benavides, and David Puerta. Eduaro Carrizoa, Orquestra Conductor says, “Colombian tiple has in Fabian Gallon its best passionate and knowledgeable interpreter. In his hands lay the responsibility of keeping the path of the development of the technique and interpretation of the instrument.”

Emerald Rae Forman, Cape Breton & Scottish fiddle player

The distinctive fiddling style of Cape Breton, Nova Scotia has roots in the strathspeys and reels brought to Canada by early 19th century Scottish immigrants. Emerald Rae Forman has mastered both Scottish and Cape Breton fiddling. She began her study with Boston based Barbara McOwen, renowned for her private library of Scottish music books. Emerald went on to compete in the US Scottish Fiddling Championships, winning the US National Champion title at 18 years old. She went on to earn degrees from Berklee College of Music and the University of Glasgow.

Fiddle and dance are closely related; to become a great traditional fiddler, it helps to know the dance steps the fiddle tunes accompany. In 2011, Emerald Rae completed a Mass Cultural Council Traditional Arts Apprenticeship in Irish step dance with Mass Cultural Council Artist Fellow Kieran Jordan. In 2016, she was awarded a Traditional Arts Apprenticeship to mentor Elizabeth Kozachek in Scottish and Cape Breton fiddle playing. Emerald Rae works as a professional performer and teacher of multiple styles of fiddle and step dance. She leads workshop at the Boston Fiddle Club and has served on the Boston Celtic Music Festival

Soumya Rajaram, Bharatanatayam dancer

Soumya Rajaram performs and teaches Bharatanatyam dance, a South Indian classical tradition with strong spiritual connections to Hindu religion and mythology. Although originally a hereditary tradition, the teaching of Bharatanatyam has become institutionalized. Indeed, Soumya came up within a deep lineage of dance teachers trained at the Kalakshetra Foundation in Chennai, India. In addition to her years of dedicated training in the technique and expressive elements of Bharatanatyam, she has extensive training in Carnatic music, which is integral to Bharatanatyam dance.

Known for her exacting standards, Rajaram is skilled in nritta (abstract dance) and abhinaya (emotive aspect). She performs regularly at festivals and concerts and is thought of highly by senior dance teachers who first brought Bharatanatyam to southern New England. Soumya is an active contributor to the India arts community in Greater Boston. She continues to enhance her learning under the mentorship of Sheejith Krishna, spending a few months a year at his studio and home in Chennai.